4 Tips for Choosing the Right Steel Pipe for Your Project Requirements

When embarking on a construction or industrial project, selecting the right materials is crucial to ensure both performance and longevity. One essential component that often demands careful consideration is the choice of steel pipes. As industry expert John Mitchell, a seasoned engineer in the steel pipe sector, asserts, "Choosing the right steel pipe is not just about quality; it's about matching the material to the specific demands of your project." This highlights the importance of understanding the unique requirements that dictate the selection process.

With various types of steel pipes available on the market, the decision can often feel overwhelming. Factors such as size, thickness, treatment, and intended application must all be taken into account. Understanding the critical elements that differentiate each type of steel pipe is essential for those involved in construction, plumbing, or any project reliant on resilience and integrity. In this article, we will explore four essential tips for choosing the right steel pipe for your project requirements, ensuring that you make an informed and effective decision.

Understanding Different Types of Steel Pipes and Their Uses

When selecting steel pipes for your project, understanding the different types available and their specific applications is crucial. One commonly used type is the seamless steel pipe, known for its durability and ability to withstand high pressure and temperature.

These pipes are ideal for industries such as oil and gas, where safety and reliability are paramount. Additionally, they are often favored in structural applications, where strength is required without the need for joints that can weaken the structure.

Welded steel pipes, on the other hand, are created by rolling metal sheets and welding them together. This style is typically used for a variety of construction projects, including water and gas lines, due to its cost-effectiveness and versatility.

The manufacturing process allows for longer lengths, which can reduce the number of joints and potential leak points. When choosing between seamless and welded options, consider factors like the nature of the fluid being transported, the operating environment, and the required pressure ratings to ensure optimal performance and safety in your project.

Evaluating Pipe Specifications: Size, Thickness, and Material Grade

When selecting steel pipes for a project, understanding pipe specifications is crucial to ensuring that you choose the right materials for your needs. The size of the pipe plays a vital role in determining flow rates and the overall efficiency of the system. It's essential to consider not only the nominal size but also how it correlates to the internal diameter, as this will affect fluid dynamics. Proper sizing can prevent common issues such as excessive pressure drop or turbulence, which can compromise the integrity of your project.

Thickness, often defined by the schedule rating, is another critical factor to consider. Thicker pipes generally provide greater strength and durability, making them suitable for high-pressure applications or environments with significant physical stress. However, it is essential to balance thickness with weight and cost, as excessively thick pipes can be cumbersome and more expensive. Lastly, the material grade of the steel pipe, which dictates its resistance to corrosion, wear, and temperature extremes, should align with the specific demands of your project. Choosing the right grade ensures longevity and reliability, making it imperative to assess environmental conditions and the nature of the materials being transported.

4 Tips for Choosing the Right Steel Pipe for Your Project Requirements

| Pipe Size (inches) | Wall Thickness (mm) | Material Grade | Max Pressure (psi) |

|---|---|---|---|

| 2 | 3.2 | ASTM A53 Grade B | 280 |

| 3 | 4.0 | ASTM A106 Grade B | 300 |

| 4 | 5.0 | ASTM A312 TP316 | 400 |

| 6 | 6.0 | ASTM A500 Grade B | 450 |

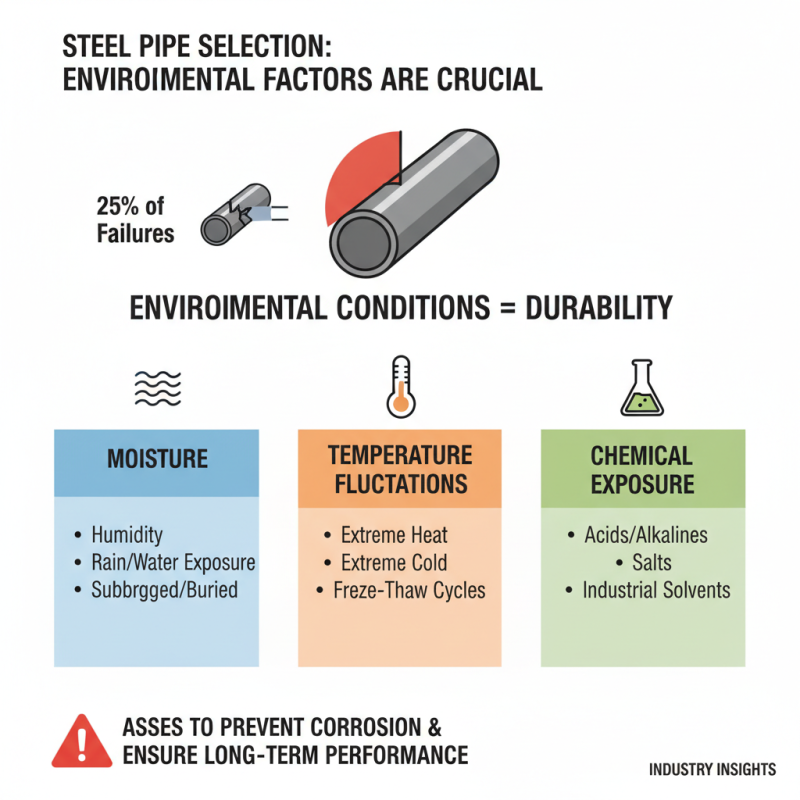

Assessing Environmental Conditions for Steel Pipe Durability

When selecting the appropriate steel pipe for your project, one of the most crucial factors to consider is the environmental conditions in which the pipe will be used. According to recent industry studies, approximately 25% of steel pipe failures are attributed to environmental factors, including corrosion caused by moisture, temperature fluctuations, and chemical exposure. Therefore, assessing these conditions is imperative to ensure long-term durability and performance.

In environments with high humidity and corrosive substances, such as near coastlines or industrial areas, selecting corrosion-resistant coatings or alloys can significantly enhance the lifespan of steel pipes. Reports from the American Society of Civil Engineers suggest that using protective measures can increase the durability of pipes by up to 50% in these harsh environments. Temperature variations can also affect material integrity; for instance, pipes subjected to extreme cold may become brittle, leading to potential fractures. Thus, understanding the specific environmental conditions and their potential impact is essential for making informed decisions regarding the right steel pipe for your needs.

Considering Cost-Effectiveness: Budgeting for Steel Pipe Projects

When embarking on a steel pipe project, it's essential to consider cost-effectiveness while making informed choices. Budgeting for steel pipes requires a thorough understanding of materials, labor, and overall project requirements. One crucial factor is to evaluate the type of steel needed based on the project’s application. Different grades of steel pipes can greatly influence costs; selecting the right grade ensures durability without unnecessary expenditure.

A practical tip for managing your budget is to source multiple quotes from suppliers before making a purchase. This helps you understand the market rates and allows you to negotiate better deals. Additionally, don't overlook the benefits of bulk purchasing—ordering larger quantities can lead to significant savings. Ensuring that you choose suppliers with a reliable track record can also prevent costly setbacks during the project.

Another aspect to consider is the long-term implications of your choice. Investing in higher-quality steel pipes may seem like a bit more upfront, but their longevity and lower maintenance requirements can lead to greater savings down the line. Additionally, consider any environmental regulations that may affect costs; opting for environmentally compliant materials can enhance your project's reputation and save on potential fines. By meticulously budgeting and making informed choices, you’ll ensure the success of your steel pipe project without compromising your financial constraints.

Compliance with Industry Standards and Regulations for Steel Pipes

When selecting steel pipes for a project, compliance with industry standards and regulations is paramount to ensure safety, durability, and efficiency. The American Society for Testing and Materials (ASTM) provides comprehensive guidelines that characterize the quality and performance of steel pipes. For instance, ASTM A53 sets specific requirements for the seamless and welded black and hot-dipped galvanized steel pipe grade, with stringent criteria on mechanical properties and dimensions. Compliance with such standards not only guarantees optimal performance but also minimizes the risks associated with project delays and legal complications stemming from non-compliance.

Moreover, the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) set forth regulations that address various aspects of steel pipe production, including material composition and testing protocols. According to the World Steel Association, over 1.5 billion metric tons of steel are produced annually, with a significant portion utilized in construction and infrastructure projects. Adhering to these regulations is critical for industries such as oil and gas, where the integrity of steel pipes can directly affect operational safety and environmental impacts. Therefore, understanding and implementing these compliance standards is essential in selecting the right steel pipes that meet both project requirements and regulatory demands.

Related Posts

-

2025 Top 10 Innovations in 4 Steel Pipe: Exploring Market Growth and Industry Trends

-

Top 10 Best Steel Pipes for Construction and Industrial Use in 2023

-

Unlocking the Secrets of Sustainable Water Solutions with Advanced Well Drilling Supplies Leading the Market Transition

-

Essential Guide to Choosing the Right Water Well Supplies for Sustainable Water Management

-

Top 10 Advantages of Using PVC Tubes in Your Home and Industry

-

Top 5 Benefits of Using Steel PVC for Your Construction Projects