How to Choose the Right Well Casing Pipe for Your Drilling Needs in 2025

Selecting the appropriate well casing pipe is a crucial step in the drilling process, significantly impacting the longevity and efficiency of the completed well. As we move into 2025, advancements in materials and technology continue to reshape the landscape of drilling operations. Understanding these developments is essential for professionals in the industry who seek to optimize their drilling strategies and ensure the integrity of their wells.

This guide will explore the various factors to consider when choosing a well casing pipe, including material types, pressure ratings, and environmental conditions. Each aspect plays a pivotal role in determining the best fit for specific drilling needs, making it imperative for drillers to stay informed about the latest trends and standards. Additionally, we will address the importance of adhering to regional regulations and best practices to enhance safety and sustainability within drilling projects.

By equipping yourself with the right knowledge and tools, you can make informed decisions about well casing pipe selection, leading to successful drilling outcomes in 2025 and beyond.

Factors to Consider When Selecting Well Casing Pipes

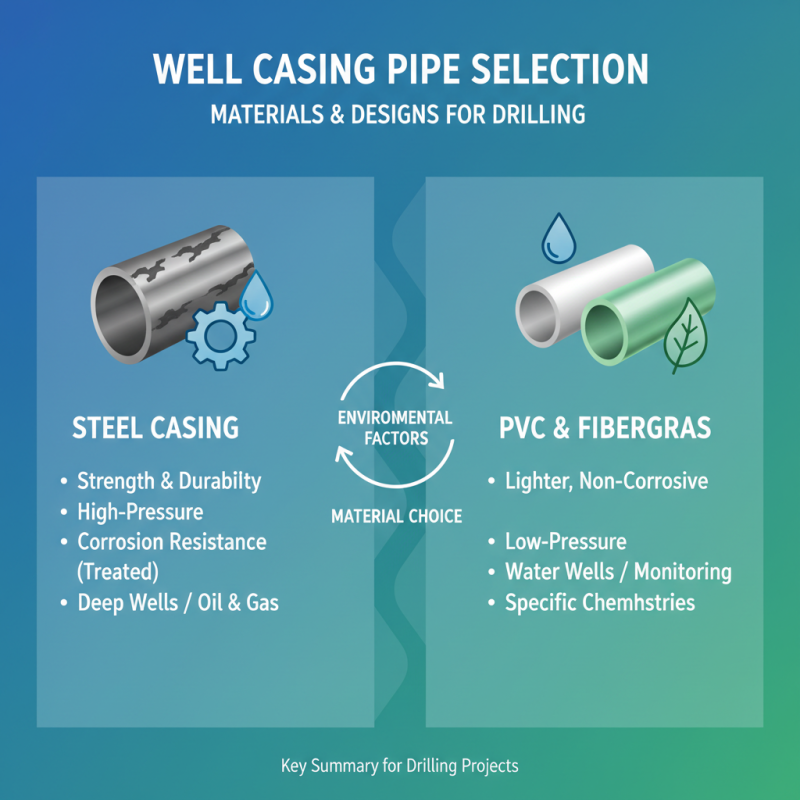

When selecting well casing pipes for drilling needs in 2025, several crucial factors should be considered to ensure optimal performance and longevity. One primary consideration is the material composition of the casing pipe. Options commonly include steel, PVC, and fiberglass, each offering distinct advantages in terms of strength, corrosion resistance, and flexibility. Steel may be preferred for its structural integrity in deeper wells, while PVC can be more cost-effective and easier to manage in less demanding environments. Evaluating the environmental conditions of the drilling site is essential in determining the best material.

Another vital factor is the casing pipe diameter and wall thickness, which impact not only the flow rates but also the overall stability of the well structure. Larger diameters can facilitate higher flow rates, while increased wall thickness provides enhanced resistance to external pressure. Additionally, considering the depth of the well and the anticipated groundwater levels will help in deciding the appropriate specifications for the casing pipe. It’s also important to factor in local regulations and any potential impacts on surrounding ecosystems when making your selection. Proper planning and informed choices can significantly enhance the effectiveness and sustainability of your drilling project.

How to Choose the Right Well Casing Pipe for Your Drilling Needs in 2025 - Factors to Consider When Selecting Well Casing Pipes

| Factor | Description | Recommended Material | Common Uses |

|---|---|---|---|

| Diameter | Size of the casing pipe | Steel | Water wells, oil wells |

| Pressure Rating | Maximum pressure the casing can withstand | PVC | Geothermal wells |

| Corrosion Resistance | Ability to resist corrosive environments | Stainless Steel | Brackish water wells |

| Length | Standard or custom lengths based on drilling depth | Fiberglass | Deep water wells |

| Regulatory Compliance | Meeting local regulations and standards | Composite Materials | Various drilling applications |

Types of Well Casing Pipes Suitable for Various Drilling Environments

When selecting the appropriate well casing pipe for drilling projects in various environments, the types of materials and designs available play a crucial role. For instance, steel casing pipes are frequently used due to their strength and durability, making them ideal for high-pressure applications. Their ability to withstand corrosive elements in certain geological formations also makes them a preferred choice. Conversely, PVC and fiberglass casing pipes present lighter and more corrosion-resistant alternatives, making them suitable for low-pressure scenarios and specific water well applications.

In addition to material considerations, the drilling environment should dictate the choice of casing pipe. For environments with a risk of contamination, such as near industrial sites, utilizing non-corrosive materials like PVC can ensure long-term integrity and safety of the groundwater. Meanwhile, in areas with unstable geology or potential for shifting soil, reinforced steel casing provides the support necessary to maintain bore stability. By assessing the geological conditions and the specific requirements of the drilling operation, one can make informed decisions that enhance both performance and safety.

Assessing Material Durability and Corrosion Resistance in Casing Pipes

When selecting the right well casing pipe for your drilling projects, assessing material durability and corrosion resistance is paramount. In 2025, the advancements in casing pipe materials offer a variety of options, including steel, PVC, and fiberglass. Steel pipes, known for their strength, can provide exceptional durability but are often susceptible to corrosion. On the other hand, PVC and fiberglass options boast higher resistance to chemical corrosion, making them a better fit in certain environments. It's crucial to evaluate the specific conditions of your drilling site, such as soil type and the presence of corrosive substances, to make an informed decision.

Tips: Consider using corrosion-resistant coatings or linings for steel casing pipes to enhance their longevity. Regular inspections of your well casing can help identify early signs of wear, allowing for timely maintenance before significant issues arise. Additionally, consult with industry experts to understand the best materials tailored to your specific drilling conditions, ensuring sustainable and reliable operations.

Sizing and Installation Guidelines for Well Casing Pipes

When selecting a well casing pipe, proper sizing is crucial for ensuring structural integrity and functionality. The diameter of the casing must accommodate the well’s intended purpose and the equipment that will be installed.

A larger diameter provides more space for pumps and other machinery, while a smaller diameter may be beneficial for limited access areas. Additionally, the depth of the well and the geological characteristics of the drilling site will influence the size of the casing. It is essential to analyze local regulations and best practices to determine the most suitable dimensions based on these factors.

A larger diameter provides more space for pumps and other machinery, while a smaller diameter may be beneficial for limited access areas. Additionally, the depth of the well and the geological characteristics of the drilling site will influence the size of the casing. It is essential to analyze local regulations and best practices to determine the most suitable dimensions based on these factors.

Installation guidelines for well casing pipes further emphasize the importance of material selection and proper techniques. The casing must be installed vertically to prevent leaning, which can compromise stability. Adequate sealing is necessary to protect groundwater from contamination; therefore, using appropriate sealing materials and methods is critical. Furthermore, employing an experienced installer can mitigate risks associated with improper handling and placement. Considering these factors during the installation process will enhance the longevity and performance of the well casing, ultimately supporting the drilling operations effectively.

Regulatory Standards and Compliance for Well Casing Selection in 2025

When selecting well casing pipes for drilling operations in 2025, adherence to regulatory standards and compliance is of paramount importance. Regulatory bodies have established specific guidelines that govern the materials, dimensions, and installation practices for casing pipes to ensure environmental protection and structural integrity. For example, the American Petroleum Institute (API) sets forth standards that dictate the testing, qualification, and application of casing materials, ensuring that they can withstand various stresses imposed during drilling and production.

In recent years, the emphasis on compliance has intensified, particularly due to growing environmental concerns. According to a National Energy Technology Laboratory (NETL) report, improper casing can lead to significant risks, including groundwater contamination and blowouts, which are not only hazardous but can also result in costly remediation efforts. As regulatory scrutiny increases, drilling companies are urged to invest in high-quality casing materials that meet the rigorous specifications outlined in the latest regulations. Failing to comply may result in fines, project delays, and potential legal ramifications.

Moreover, staying informed about local and federal compliance changes is crucial for operators. For instance, the EPA has updated its guidelines to include more stringent requirements on the environmental impact assessments for well installations. In 2025, drilling companies must not only focus on the technical specifications of the casing pipe but also integrate rigorous compliance checks into their operational protocols to avoid violations and ensure sustainable practices in well drilling.

Related Posts

-

Understanding the Benefits and Applications of PVC Water Pipes in Modern Plumbing Systems

-

2025 Top Guide to Using 4 Inch PVC Pipe for Your Projects

-

2025 Top 10 Innovations in 4 Steel Pipe: Exploring Market Growth and Industry Trends

-

Unlocking the Secrets of Sustainable Water Solutions with Advanced Well Drilling Supplies Leading the Market Transition

-

Understanding the Importance of Water Well Pipe Selection for Safe Water Access

-

2025 Top 10 PVC Tubes Innovations Driving the Market with 10 Billion Dollar Growth Potential