8 Essential Tips for Choosing Between Steel and PVC for Your Next Project

In the dynamic world of construction and materials, the choice between steel and PVC is often a pivotal factor in determining the success of a project. As John Smith, a renowned expert in the steel PVC industry, aptly puts it, "Selecting the right material for your project is not just about durability; it’s about aligning with your specific project needs and environmental considerations." This statement encapsulates the essence of the decision-making process that many project managers and builders face when weighing the advantages and disadvantages of these two materials.

Steel is revered for its superior strength and longevity, making it an ideal choice for heavy-duty applications. In contrast, PVC boasts ease of installation and resistance to corrosion, which can be particularly advantageous in specific environments. With sustainability becoming increasingly critical in construction, understanding the benefits of both steel and PVC is essential for making informed decisions that balance cost, performance, and environmental impact.

In this article, we will explore eight essential tips that can guide professionals and DIY enthusiasts alike in making the right choice between steel and PVC for their upcoming projects. By examining factors such as cost-effectiveness, application suitability, and maintenance requirements, we aim to provide clarity in the often complex world of material selection, ensuring your project stands the test of time.

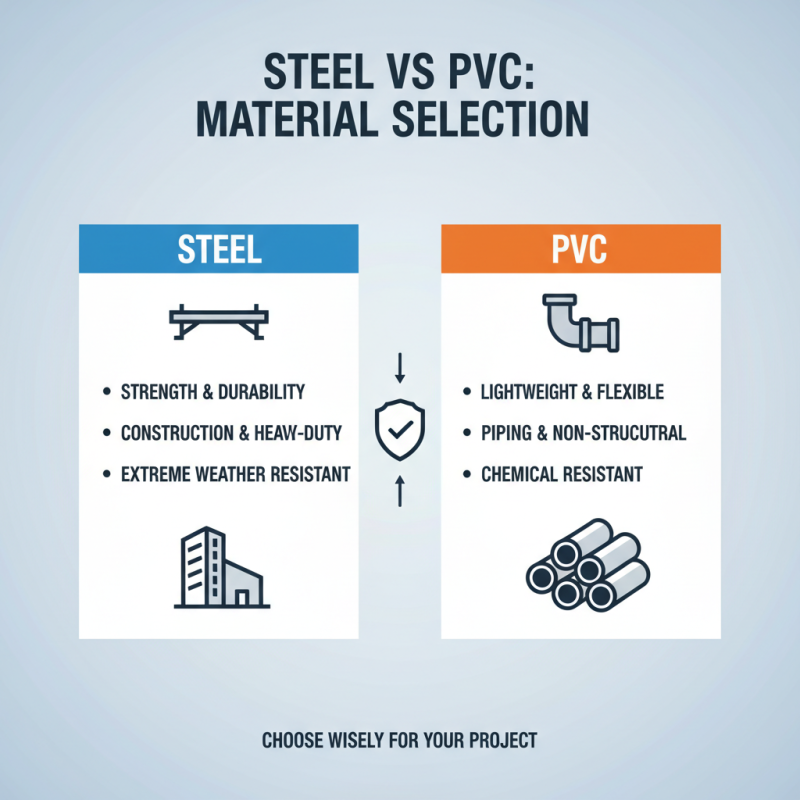

Understanding the Key Differences Between Steel and PVC Materials

When selecting materials for your next project, understanding the key differences between steel and PVC is crucial. Steel is known for its exceptional strength and durability, making it ideal for structures that require high load-bearing capabilities. Its resistance to weathering and fire adds to its longevity, making it a popular choice for construction and heavy-duty applications. On the flip side, PVC is lightweight, corrosion-resistant, and easier to handle, which can reduce labor costs. This plastic material excels in applications needing flexibility and is often used in plumbing, window frames, and outdoor furniture.

Tip 1: Consider the environment of your project. If you’re working in an area prone to harsh weather conditions, steel may be the better option due to its resilience. Conversely, if ease of installation and lower maintenance is a priority, PVC could provide substantial advantages.

Tip 2: Assess the load requirements of your project. Steel's superior strength makes it ideal for applications involving heavy loads, while PVC is generally more suitable for lighter applications. Understanding these load capacities can help prevent potential failures down the line and ensure your project’s success.

Choosing between steel and PVC ultimately depends on the specific needs of your project, including the required strength, environmental considerations, and budget constraints.

Factors to Consider in Material Durability and Longevity

When deciding between steel and PVC for your next project, understanding material durability and longevity is crucial. Steel, renowned for its strength and resilience, has a lifespan of up to 50 years with proper maintenance. According to the American Institute of Steel Construction, steel's ability to withstand extreme weather conditions and high-stress loads makes it a preferred choice in construction and structural applications. However, it requires protective coatings to prevent corrosion, particularly in marine or humid environments, which can add to the overall maintenance costs.

On the other hand, PVC offers notable advantages in terms of resistance to decay, chemical exposure, and moisture. Studies from the Vinyl Institute indicate that PVC materials can last for over 30 years without significant degradation, making them suitable for outdoor applications like fencing, decking, and piping. Their lightweight nature simplifies transportation and installation, while their inherent resistance to rot means less need for maintenance. Factors like installation environment, expected load-bearing requirements, and long-term care should guide the decision between these two materials, ensuring a choice that aligns with both functionality and durability goals.

Cost Analysis: Comparing the Expenses of Steel vs. PVC

When it comes to material selection for construction projects, the cost is often a primary concern. Recent industry reports indicate that the price of steel varies widely, typically ranging from $600 to $850 per ton, depending on market conditions and specific grades. Additionally, steel's fabrication costs and potential for long-term durability can add to its initial expense, making it crucial to factor in these elements for a comprehensive cost analysis. Specifically, projects that require structural integrity and longevity may find that the higher upfront costs of steel are offset by its reduced maintenance requirements over time.

On the other hand, PVC remains an attractive alternative due to its lower initial costs, often priced between $2 and $4 per linear foot for standard applications. The lightweight nature of PVC allows for easier handling and installation, which can significantly reduce labor costs. According to a 2022 report from the International Institute of Building Materials, projects utilizing PVC can achieve up to 30% savings on initial expenditures compared to those using steel. However, it is essential to consider the long-term implications, as PVC's lifespan is generally shorter and may lead to increased replacement and maintenance costs in the future. Balancing these factors is critical for making an informed choice for your next project.

8 Essential Tips for Choosing Between Steel and PVC for Your Next Project - Cost Analysis: Comparing the Expenses of Steel vs. PVC

| Material | Initial Cost per Ton ($) | Durability (Years) | Maintenance Cost per Year ($) | Weight (lb/ft3) | Environmental Impact |

|---|---|---|---|---|---|

| Steel | 700 | 50 | 200 | 490 | High Recyclability |

| PVC | 500 | 25 | 50 | 75 | Low Recyclability |

Environmental Impact: Assessing Sustainability of Steel and PVC

When considering the environmental impact of steel versus PVC for your next project, it is essential to assess the sustainability of both materials. Steel is known for its longevity and recyclability. According to a report by the World Steel Association, steel is 100% recyclable without loss of quality, and approximately 85% of steel products are recycled at the end of their life cycle. This ability to reuse resources significantly reduces the carbon footprint associated with production and limits the demand for new raw materials.

On the other hand, PVC offers advantages in terms of lower energy consumption during production. A life cycle assessment from the European Commission reveals that the production of PVC requires about 60% less energy compared to steel. However, concerns regarding PVC's environmental impact arise due to its potential release of harmful substances during manufacture and disposal. Reports from environmental organizations have indicated that while PVC can be recycled, the rates are substantially lower than that of steel, with only about 5-10% of PVC products being recycled globally. Thus, while both materials have their pros and cons, understanding their complete environmental profiles is crucial for making an informed choice in sustainability-focused projects.

Environmental Impact: Assessing Sustainability of Steel and PVC

Applications and Suitability: When to Use Steel or PVC in Projects

When selecting materials for your next project, understanding the applications and suitability of steel and PVC is essential. Steel, known for its strength and durability, is often favored in construction and heavy-duty applications, such as structural components in commercial buildings. According to a 2020 report by the American Institute of Steel Construction, steel can withstand significant stress and impact, making it a preferred material in safety-critical structures. Moreover, steel's resistance to extreme weather conditions adds to its longevity in outdoor applications, ensuring that projects remain secure for decades.

On the other hand, PVC offers advantages for applications requiring corrosion resistance and lightweight properties. It is commonly used in plumbing and electrical conduits, where exposure to moisture and chemicals is a concern. The PlastiFacts report highlighted that the use of PVC in construction could reduce energy costs by up to 30% due to its insulating properties. Additionally, PVC is easier to install and handle compared to steel, making it an attractive option for residential projects and DIY renovations. The choice between steel and PVC ultimately hinges on the specific requirements of the project, including factors like load-bearing needs, environmental exposure, and cost considerations.

Related Posts

-

Top 5 Benefits of Using Steel PVC for Your Construction Projects

-

The Evolution of Plastic Pipe: Sustainable Solutions for Modern Infrastructure

-

10 Essential Well Pump Supplies You Need for Optimal Water System Performance

-

2025 Top Guide to Using 4 Inch PVC Pipe for Your Projects

-

Essential Guide to Choosing the Right Water Well Supplies for Sustainable Water Management

-

2025 How to Choose the Best PVC Well Pipe for Your Water System