10 Essential Well Pump Supplies You Need for Optimal Water System Performance

In the realm of residential and agricultural water systems, the importance of well pump supplies cannot be overstated. According to a recent industry report by the Water Systems Association, approximately 15 million households in the United States rely on private well systems for their water needs, underscoring the significance of maintaining optimal functionality. Proper well pump supplies not only ensure a consistent water supply but also enhance the longevity and efficiency of the entire water system.

Expertise in this field is vital, as emphasized by Dr. Emily Carter, a leading researcher in groundwater systems. She states, "Utilizing the right well pump supplies is crucial for achieving maximum efficiency and reliability in any water system." The selection of essential components can significantly impact the performance of pumps, influencing factors such as flow rate, energy consumption, and overall system durability. A comprehensive understanding of these supplies is essential for both DIY homeowners and professionals alike to safeguard their water resources effectively.

Essential Components of a Well Pump System for Efficiency

A well pump system is integral for providing a reliable water supply, and its efficiency hinges on several essential components. Among these, the pump itself plays a pivotal role, with reports indicating that well pumps can operate with over 90% efficiency when properly maintained. Choosing a pump that aligns with your well depth and water requirements significantly reduces energy consumption, ultimately extending the system's lifespan.

Moreover, well pump supplies such as pressure tanks, check valves, and control switches are crucial for ensuring optimal performance. According to industry studies, pressure tanks help maintain consistent water pressure and enhance energy efficiency by reducing the frequency of pump cycling—this can save users approximately 20-30% on energy costs over time. Regular inspections and replacements of these components are vital for avoiding service interruptions and costly repairs.

Tip: Always consult with a professional to assess your well system's components, ensuring everything from cables to fittings meets the specific demands of your setup. Regular maintenance checks can prevent minor issues from escalating into significant failures. Additionally, consider investing in high-quality materials; the initial cost can lead to substantial long-term savings on repairs and inefficiencies.

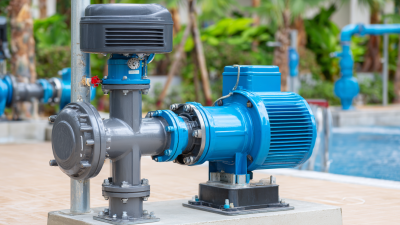

Understanding Pump Types: Submersible vs. Jet Pumps in Water Systems

When it comes to optimizing your water system's performance, understanding the different pump types is crucial. Two of the most common types of well pumps are submersible pumps and jet pumps. Submersible pumps are designed to operate underwater, pushing water to the surface through a discharge pipe. They are known for their efficiency, with reports indicating that they can operate at over 90% efficiency, making them ideal for deep wells that require substantial lifting. According to a study by the Water Systems Council, submersible pumps are preferred in about 70% of residential groundwater applications due to their high reliability and energy efficiency.

On the other hand, jet pumps operate by creating a vacuum to draw water up from the well and are typically used in shallow wells or as booster pumps. While they can be less efficient, with average efficiencies ranging from 50-65%, jet pumps have the advantage of being easy to install and repair, which makes them attractive for homeowners looking for accessibility. A report from the U.S. Geological Survey highlights that the choice between these two pump types can significantly influence water system performance and maintenance costs over time. Understanding these differences allows homeowners to make informed decisions that align with their specific water needs and geographical conditions.

Key Tools for Installation: Ensuring Proper Well Pump Setup

When setting up a well pump system, having the right tools is crucial for ensuring proper installation and optimal performance. Essential tools include a pipe wrench, which is vital for securing and adjusting fittings; a level to ensure that your pump is installed correctly; and a torque wrench to help with fastening bolts accurately. These tools not only facilitate a smoother installation process but also protect against potential malfunctions caused by improper setup.

Tips for installation include checking local building codes before beginning, as regulations may dictate specific requirements for well pump systems. Additionally, ensure that all components are compatible with each other to prevent future issues. It's also wise to have spare gaskets and seals on hand, as these parts can wear over time and may require replacement during maintenance checks.

Finally, invest in a quality water pressure gauge to monitor your system’s performance after installation. Regularly checking pressure levels will help you identify any irregularities early, ensuring your water system runs efficiently for years to come. Remember, a well-installed pump not only optimizes water flow but also enhances the lifespan of the entire system.

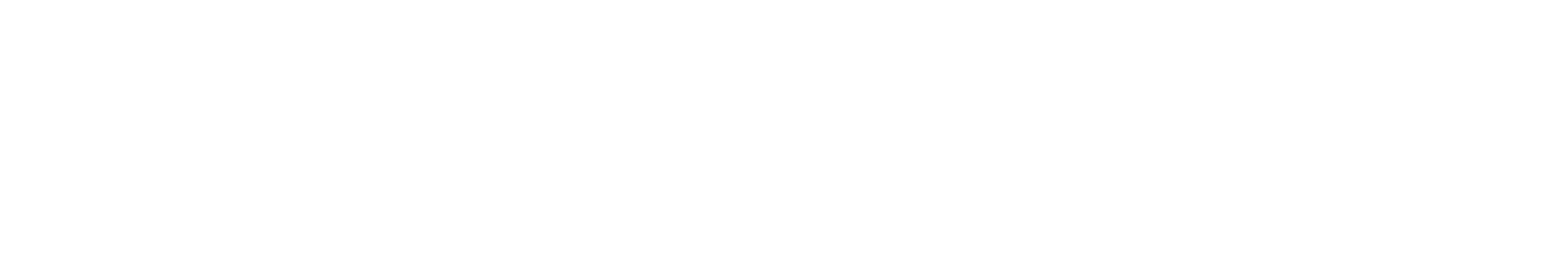

Maintenance Supplies to Extend the Life of Your Well Pump

Maintaining the performance and longevity of your well pump is essential for ensuring a reliable water supply. According to the National Ground Water Association (NGWA), proper maintenance can extend the average lifespan of a well pump from 10 years to over 15 years, significantly reducing the need for early replacements and associated costs. Regular inspections and maintenance supplies such as water quality testing kits, pump oil, and cleaning agents play a crucial role in this process. These supplies help detect potential issues, ensuring that your pump operates efficiently and remains in good condition.

In addition to basic maintenance, other supplies like check valves and pressure gauges can enhance system performance. Pressure gauges help monitor the system's water pressure, allowing for timely adjustments that optimize flow rates and prevent damage. Furthermore, investing in high-quality parts, such as submersible pump cables and seals, can prevent wear and tear that leads to costly repairs. Research shows that well pumps that undergo regular maintenance experience 30% fewer breakdowns, emphasizing the importance of having the right supplies on hand to maintain optimal performance for years to come.

Troubleshooting Equipment: Diagnosing Well Pump Performance Issues

When dealing with well pump performance issues, having the right troubleshooting equipment is crucial for accurate diagnosis. Start with a multimeter, which allows you to check electrical connections and gauge voltage levels. This tool helps identify potential electrical failures that could disrupt the pump's operation. Additionally, a pressure gauge is essential for measuring system pressure, ensuring that the pump is functioning within the required limits. Regularly checking pressure can prevent minor issues from becoming significant failures.

Another important tool is a flow meter, which measures the water output and helps assess whether the pump is delivering the expected amount of water. If the water flow is lower than anticipated, it may indicate blockages or wear in the pump system. Lastly, a set of wrenches and screwdrivers may seem basic, but having the proper tools at hand facilitates quick adjustments or repairs during troubleshooting. By equipping yourself with these essential items, you can effectively diagnose and resolve well pump performance issues, ensuring your water system operates efficiently.

10 Essential Well Pump Supplies You Need for Optimal Water System Performance

| Supply Item | Description | Purpose | Common Issues |

|---|---|---|---|

| Pressure Switch | Device that controls the pump operation based on pressure levels. | Maintains consistent water pressure. | Pump cycles too frequently or not at all. |

| Pump Controller | Electronic device that automates pump operations. | Enhances efficiency and reduces manual operation. | Pump not responding or erratic behavior. |

| Submersible Pump | Pump designed to be submerged in water. | Pumps water from well directly. | Low or no water output. |

| Check Valves | Valves that prevent backflow of water. | Keeps pressurized water in the system. | Water drains back into the well. |

| Pressure Tank | Tank that stores water under pressure. | Provides steady water flow and pressure. | Pressure fluctuations or constant cycling. |

| PVC Pipe | Plastic pipe used for water transport. | Connects various systems. | Leaks or breaks in the pipe. |

| Water Filtration System | System to purify well water. | Removes contaminants for safe drinking. | Cloudy or foul-smelling water. |

| Teflon Tape | Tape used for sealing threaded joints. | Prevents leaks in plumbing connections. | Leaky pipes or fittings. |

| Wire and Electrical Components | Electrical supplies for pump operation. | Ensures electrical connectivity. | Pump not starting or stopping unexpectedly. |

| Hose Clamps | Metal bands that secure hoses to fittings. | Prevents hose disconnection. | Hose leaks or comes off. |

Related Posts

-

Essential Guide to Choosing the Right Water Well Supplies for Sustainable Water Management

-

Why You Need a Reliable Water Pump System for Efficient Water Management

-

Understanding the Importance of Water Well Pipe Selection for Safe Water Access

-

Exploring the Latest Innovations in Pipe Supplies: What You Need to Know for Your Projects

-

Unlocking the Secrets of Sustainable Water Solutions with Advanced Well Drilling Supplies Leading the Market Transition

-

2025 Top 10 Innovations in 4 Steel Pipe: Exploring Market Growth and Industry Trends